07517 434947

Sharpening Animal Clippers

A5 Small Animal Clippers

Most professional grooming clippers use A5-type blades, which can be sharpened many times if handled correctly. Achieving consistent, smooth cutting performance, however, requires far more than a flat whetstone.

At Certified Sharpeners, A5 blades are serviced on specialist precision machinery that restores the factory-correct hollow grind profile. Each pair is checked on a dedicated depth-of-grind jig, ensuring that no more than 0.002” and no less than 0.001” is removed — preserving blade life while restoring full performance.

Final assembly and spring tension are set using purpose-built jigs and calibrated gauges, producing repeatable, reliable results that professional groomers can depend on.

A2 A6 A7 Larger Animal Clipper Blades

A2, A6, and A7 blades are all part of the wide-format clipper system used for horses, cattle, and other large animals. Each type is designed for specific coat conditions and finishes.

•A2 Blades – Deliver a medium cut, leaving a slightly shorter coat than A6 blades. Ideal for general horse clipping where a smooth, even finish is desired.

•A6 Blades – A coarser blade used for thicker coats or first clips on horses and cattle. Leaves approximately 3 mm of hair.

•A7 Blades – The most aggressive “dirty cattle” blade, designed for matted, heavy, or slightly dirty coats. Also leaves around 3 mm, but with fewer, deeper teeth to handle resistant hair and dirt more effectively.

Although all three share similar cutting lengths, their tooth count and spacing determine how efficiently they handle differing coat types.

Clipper blades are produced in a wide range of lengths and tooth patterns to achieve the required finish. Counter-intuitively, the higher the blade number, the shorter and finer the cut — for example, a #50 blade cuts very close, while a #3 leaves a longer coat.

At Certified Sharpeners, each large-animal blade set is ground on precision machinery that restores the correct hollow profile and tooth geometry, then re-set for exact spring tension and comb alignment — ensuring reliable, smooth performance in demanding clipping conditions.

Sharpening Clipper Blades The Correct Way

We employ a Swiss-designed Heiniger machine manufactured by Liscop, a German company. This machine features a high-speed rotating, specially profiled micro-grooved aluminium disc (a conical profile) specifically designed for clipper blade sharpening. This disc is equipped with micro grooves machined into its face, similar to an old-style LP record. Prior to use, the disc is loaded with sacrificial oil as lubricant and abrasive powder, creating the grinding surface. We have two types of discs in our possession: A2, A6, and A7, which are specifically designed to accommodate large animal blades, such as horse and cattle clippers.

Certified Sharpeners think this twin disc option is a better approach than some other machines that have one face suiting all blades but not maximising and the geometry and optimising performance for the particular type.

Sheep clippers cannot be sharpened on the equipment we have. However we can sharpen dagging shears click here

Sharpening with The Lightest Touch

When we sharpen your A2 or A6 blades we remove the minimum material at every grind, giving you better blade life and less expense overall.

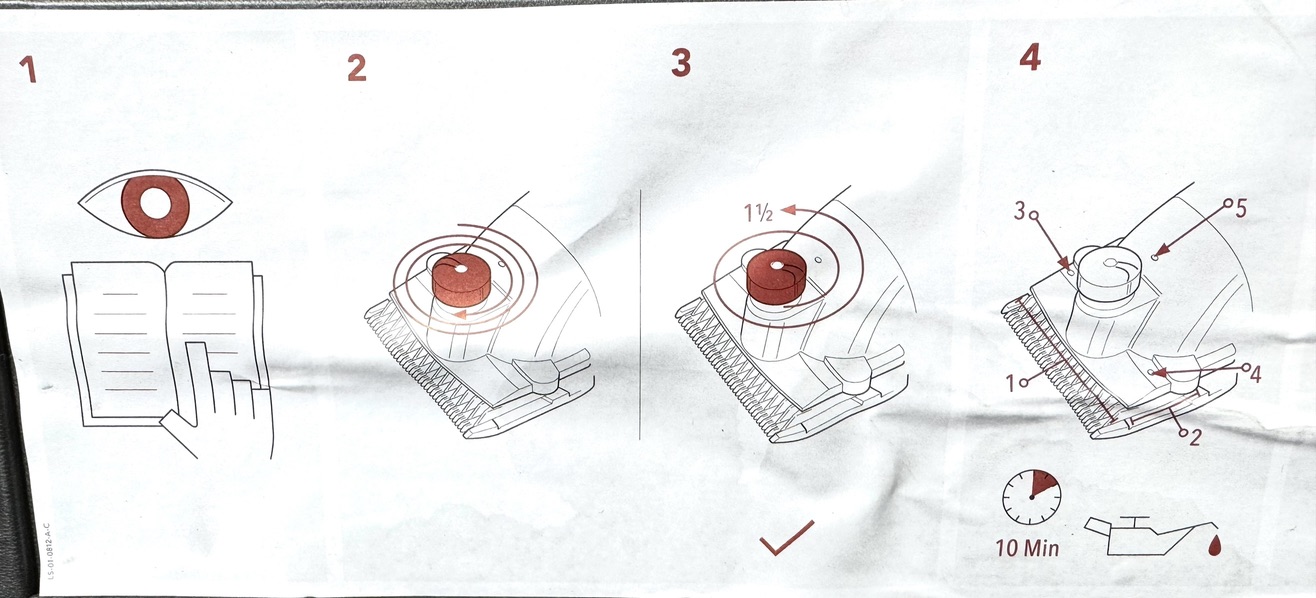

Setting the Correct Clipper Blade Tension A2 A6 & A7

On A5 clippers the tension is preset with a spring and is fixed fixed, for other larger clippers the correct tension is vital for efficient cutting and long blade life. It controls the pressure between the comb and cutter, ensuring clean shearing without overheating or excessive wear.

To set the tension an tighten fully, then back off one and a half turns — the standard procedure recommended by most manufacturers, including Lister. This provides the correct balance between contact pressure and free movement of the blades.

During use, apply a few drops of clipper oil every ten minutes to keep the blades cool and lubricated. The preferred choice is a high-quality pure mineral oil (pharmaceutical grade), apply as shown in the accompanying image from the Lister operating manual.

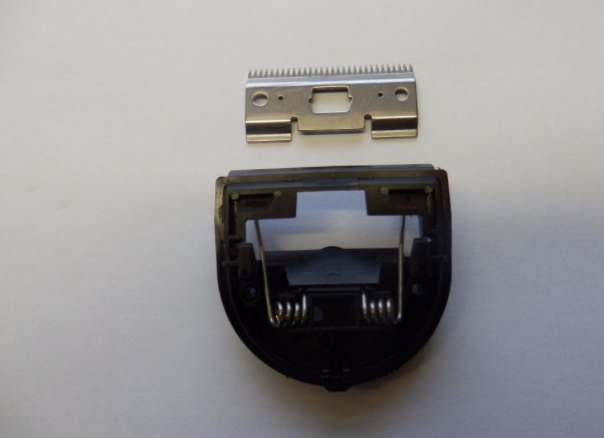

Wahl Arco 5 in one

These adjustable clipper systems are somewhat unusual in that the user can select different cutting lengths using the built-in adjustment lever.

The cutter assembly, however, is a cost-saving design. Only the comb (the lower blade) is made from solid, high-quality steel and can be reliably re-sharpened. The cutter (upper blade) is case-hardened, meaning it has a very thin hard surface layer over a softer steel core. Once this hardened skin is ground away, the exposed metal is too soft to retain a durable edge, and performance quickly deteriorates.

For that reason, the cutter is regarded as single-use. The only proper remedy for a blunt or damaged cutter is replacement, not re-sharpening. Unfortunately, genuine replacement parts can be difficult to source. At Certified Sharpeners, we hold stocks of new plastic body and spring assemblies along with replacement cutter blades. When these components are supplied, we will sharpen the comb free of charge to ensure the set performs as new.

Clipper Lubrication

It’s important to lubricate clippers, they are a highly stressed, very accuratly finished items. To thiis end we can supply you with a small needle oiler, as seen here ready filled with surgical grade pure mineral oil the best for your clippers, free of charge.

This high grade material will not stain coats nor give any irritation to the animal as it’s clinically inert.

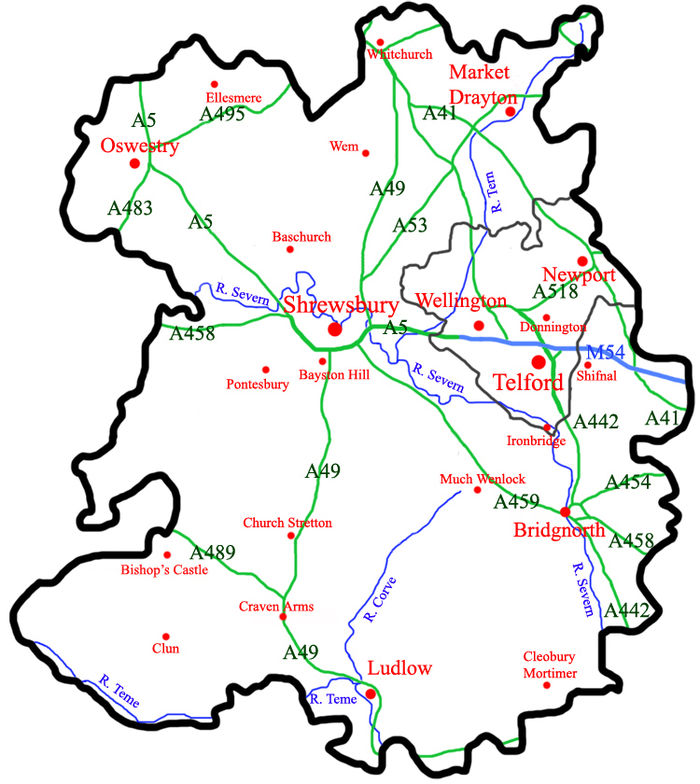

Riddles,

Back Lane

Bomere Heath

Shropshire

SY4 3PL

Our Location

Our Workshop