07517 434947

Treat You And Your Knife To The Ultimate Edge

Use A Professional Sharpener With An Edge

Better than factory edge

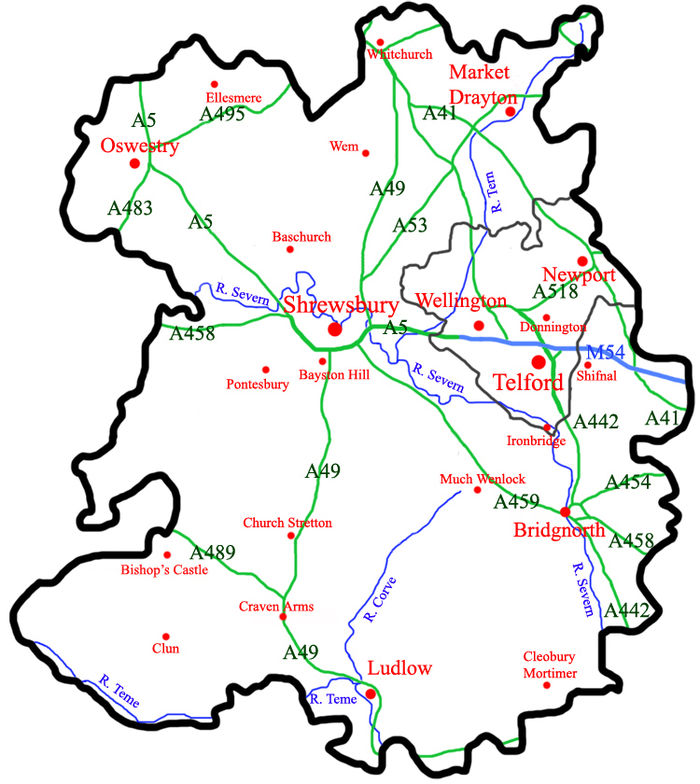

Now you can treat you knives to professional knife sharpening in Shrewsbury, and it’s available by post too, right through the UK.

There’s no point in a blunt knife; sharpness is the reason for the blade’s very being. Professional knife sharpeners, Certified Sharpeners, have the know-how to produce that ultra edge and replicate it with extreme accuracy on almost any blade, including powder steels, bringing you a product that typically outperforms the ex-factory product by a good margin .

A good knife is a good tool; a good knife that’s sharp is an excellent tool, producing paramount results with minimal effort.

Specialist Knife Sharpening For Chefs

King of the professional chef’s tools is the knife. Costing considerable amounts of money and very much cared for by their owners, they need to be sharpened by equally dedicated and qualified professional sharpeners.

Single sided Santoku Chef’s Knives, left handed

Sharpening Kitchen Knives

Domestic users may not use the calibre of knives the chef uses, but many keen cooks very much do. However, that does not mean they have to accept second-best; the mundane knife of no repute deserves to be good and sharp. We use exactly the same processes to get the keenest practical edge.

Sharpening Other Knives

Knives, of course, come in many shapes, sizes, and varieties of duties. That doesn’t really matter too much as most follow the came principle. Some are flexible, some stout, some pointy, some straight. It matters not; the same principles apply, and the outcome is a sharpened blade, and we can even sharpen those herb knives (Mezzaluna) that need a keen edge to be effective.

Powder Knives: Precision Sharpening Of Advanced PM Steels

Powder metallurgy (PM) steels are transforming today's high end knife production. Steels such as SG2, R2, M390, HAP40, CPM-154 and S35VN offer exceptional sharpness, wear resistance and durability — but they are far beyond the capability of standard sharpening systems.

At Certified Sharpeners, we offer true precision sharpening for high performance knives advanced steels such as HAP40, SG2, M390 steels with Vanadium carbide and a range of other “super” steel bladed knives. We do this using synthetic CBN abrasives on our dedicated machinery.

Click here for our page dedicated to this technology

Our Sharpening Process

Appraise & Preparation

The first thing we do is inspect the blade; it’s rare for them to be perfect. All we see are, of course, blunt, but they may be nicked, torn, or be damaged in some other way, a broken tip or bellied blade. We pre-grind almost every knife in a machine that gets the blade smooth, with no nicks and is equally bevelled to an angle of around 15°. This is done dry but using a special abrasive, CBN or Cubic Boron Nitride; this has the unusual characteristic of producing very little heat in the process of material removal, so the hardening of the knife is undamaged.

Stage 2 The Wet Grind

We use a dedicated machine from Sweden called the Tormek T8 to finish grind knives. This has a water-immersed grinding wheel with various grade grits. When we grind on this, the waste metal is washed away with the water and collected by magnets, and the blade is kept literally stone cold by the water.

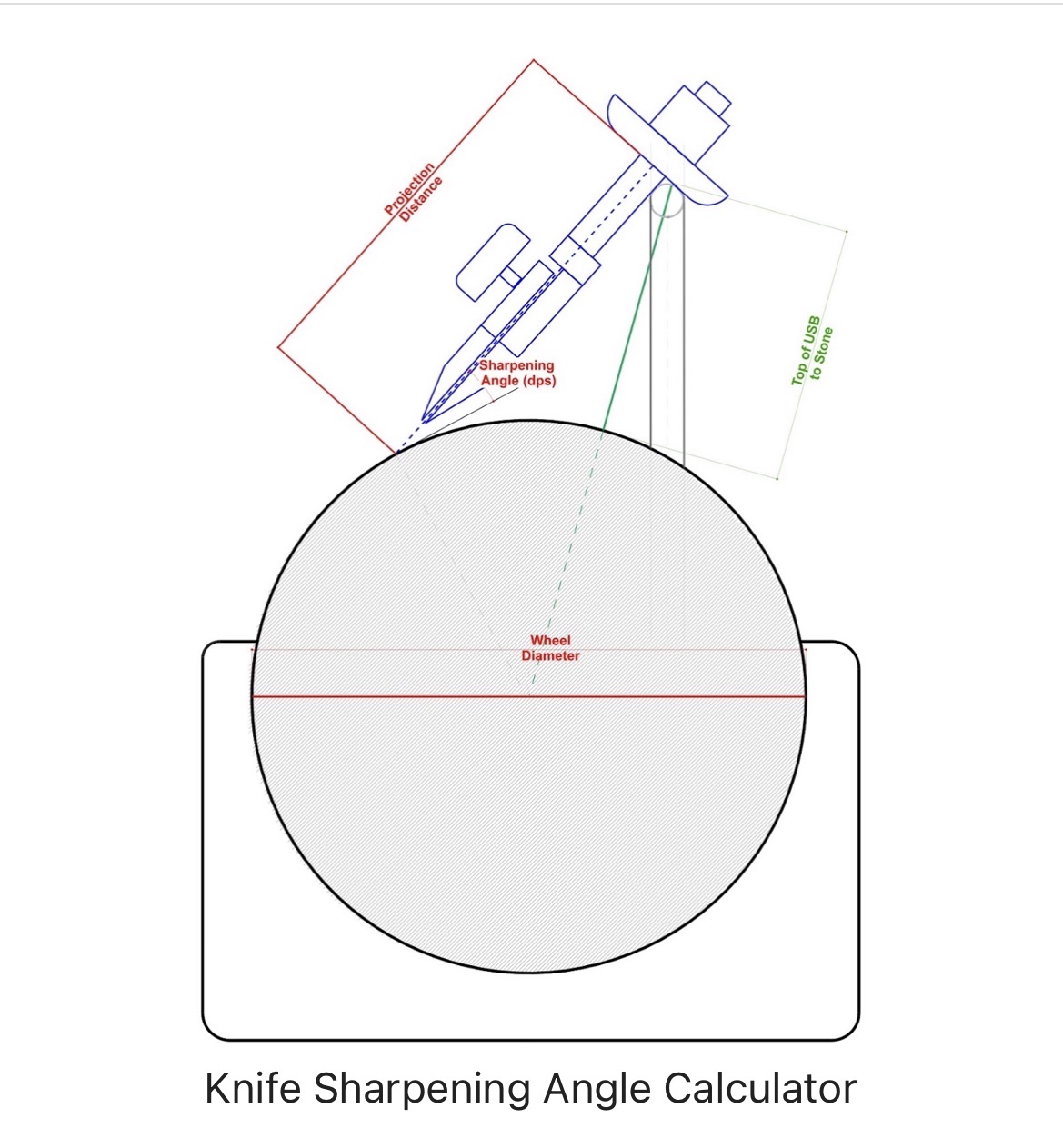

Precision Angle Set Up By Trigonometry

Implementing trigonometry is essential for absolute accuracy and repeatability. Using the grinding wheel diameter as the base measurement we have developed an app to set the blade edge for a precise grind. The distance from the wheel to the jig rest is calculated and this height provides the grind angle. Thus the grind angle is consistent regardless of the blade width. The machine is water-cooled and debris is flushed away. The final variable is the coarseness of the wheel, which is preset with a diamond honing plate. This returns the edge roughness which is then honed to achieve an exceptional fine finish.

Under Water Sharpening

Our Tormek T8 grinds a new edge while underwater; zero heat is generated and passed to the blade, no loss of temper, so no damage and minimal material removed, with all the cut metal flushed away and captured by magnets.

Power Hone

We use several honing techniques; the methods and materials used are dependent on the products we are working on. Here is a polishing mop with white-grade polishing media designed for stainless steel.

Finish Polish

One final polish on the mop with nothing except an edge shine added to make for a good finish.

Sharpness Test

Will the new, sharpened edge perform? This one certainly does - all are tested like this.

Riddles,

Back Lane

Bomere Heath

Shropshire

SY4 3PL

Our Location

Our Workshop