07517 434947

Professional Powder Steel Knife Sharpening

Powder Metalurgy

Powder metallurgy (PM) steels have revolutionised modern knife products. Steels such as SG2, R2, M390, HAP40, CPM-154 and S35VN offer exceptional sharpness wear resistance and durability but are beyond the capability of standard sharpening systems.

At Certified Sharpeners we use CBN (Cubic Boron Nitride) abrasives on our CatraSharp and Tormek T8 machines enabling us to sharpen powder steel knives to or beyond factory standards with a final diamond hone & polish,

Most sharpeners are unable to work on these steels but we can and do so regularly.

What Are Powder Steel Knives?

Powder steel knives are produced using a manufacturing method called Hot Isostatic Pressing (HIP), where a carefully crafted blend of powdered metals is melted and compressed evenly under extreme heat and pressure.

The result is a steel with:

Exceptional homogeneity — no internal weak spots

Very fine carbide distribution — vanadium, tungsten, chromium, etc

High hardness with added toughness

Superior wear and corrosion resistance

Powder metallurgy steels combine ultra-hard carbides such as vanadium and chromium with structural toughness such as is used in the production of high-performance jet engine turnbine blades, the hardness & durability of such material is well suited to knives for professional kitchens and other demanding users.

Advantages of Powder Steel Knives

Outstanding Edge Retention

Fine vanadium and tungsten carbides give PM steels extraordinary wear resistance. A PM blade will hold its edge far longer than conventional stainless or carbon steels of equal sharpness (angle)Increased Toughness and Durability

Despite their high hardness, PM steels resist chipping better than others because the carbide structure is even and predictable. There are fewer flaws in the steel and it has a smaller crystalline structureHighly Corrosion-Resistant

Alloys such as M390 and SG2 excel in professional environments where moisture and acids are found to be common.Precision Steel for Complex Blade Shapes

PM steels can be ground into very thin, stable profiles while maintaining exceptional strength. They are stiffer per unit of width

The Downsides

Important to Know Before You Buy

Vanadium and tungsten carbides are far harder than the abrasives used on water stones, whetstones, or conventional belt grinders.

Most sharpeners cannot sharpen these steels effectively because:

Aluminium oxide belts and stones cannot cut the carbide structures, nor can ceramic, only a diamond or CBN can grind the PM steel

Water stones glaze instantly as their ceramic abrasive surface is compromised by the harder substances in the PM product

The blade overheats under pressure, friction rather than cutting rubs the steel by the friction caused

A weak, short-lived wire edge forms.

PM steels will only sharpen on Diamond or CBN systems.

Limited Number of Trained Sharpeners

Many sharpening services declare these steels “unsharpen-able”. We specialise in them and sharpen them weekly

Higher Purchase Costs

PM knives can cost significantly more than standard kitchen knives — but that cost reflects the performance and longevity.

Professional Powder Steel

Sharpening Processes

Precision CBN Sharpening on the CatraSharp & Tormek T8

CBN is one of the only two abrasives capable of cutting vanadium and tungsten carbides cleanly and without excess heat, the other is diamond. Our CatraSharp uses such material but has a fixed edge angle of 15° per side, the inclusive angle of 30° offers extreme sharpness coupled with maximum robustness. For those requesting specific angles we have a CBN wheel equipped Tormek T8 which employed for finishing to precise angles of choice and suitability

Our method includes:

Accurate angle setting (as per knife design or customer preference)

Progressive CBN abrasive refinement

Controlled heat management for steel stability

Optional cutting-edge micro-geometry finish for specific tasks

Final inspection under digital microscope magnification

This methodology restores the edge to — and frequently beyond — factory performance.

Steels We Regularly Sharpen Include:

SG2 / R2 / Super Gold 2

HAP40

S35VN / S45VN

CPM-154

M390 / CTS-204P / Elmax

And other powder steel formulations

If you’re unsure whether your knife is PM steel, feel free to ask — we can identify most grades.

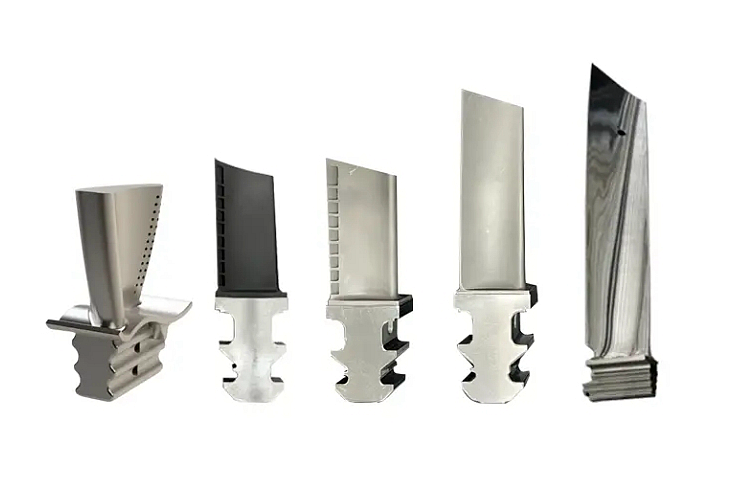

Our CatraSharp Uses CBN Wheels

254 mm diameter CBN Wheel Which Fits The Tormek

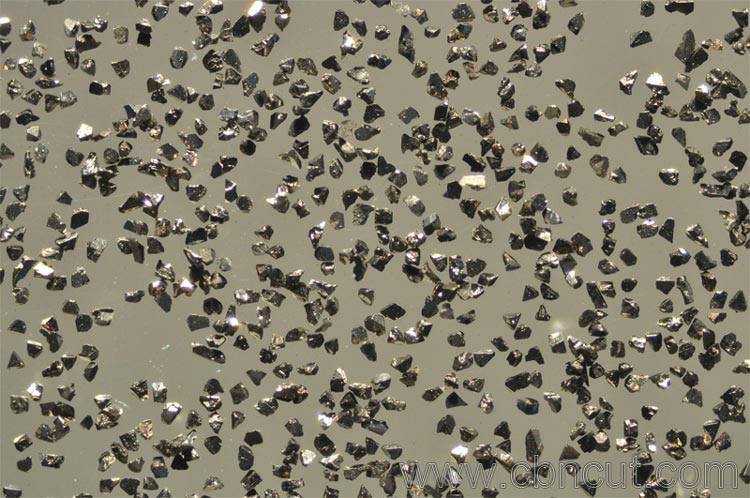

CBN Grit Held In A Tin Substrate

Knife Edge Angle Reference

Certified Sharpeners – Precision Edge Services

Common Edge Angles, per side inclusive typical use

9° / 18° Ultra-keen, very fragile. Risk of chipping in VG10.

10° / 20° Extreme sharpness, very light prep work only.

12° / 24° Fine Japanese double bevels. Takamura VG10 sweet spot.

15° / 30° General Japanese chef’s knives – balance of sharpness / durability.

17° Robust single bevel for handed knives (ura ~0°, bevel ~17°).

20° / 40° Western knives, prioritises durability.

Angles For Various Steel Recommendations

VG10: 12–15° per side recommended. 9–10° only for delicate use.

SG2 / R2: Can tolerate 10–12° due to higher hardness.

Aogami / Shirogami: 12–15° per side; reactive, so edge care is key.

Western stainless: 15–20° per side for durability.

Convexing the Edge

A slight arch with the power hone strengthens the edge apex while retaining keenness. Think of blending the shoulder into the edge rather than forming a hard V. This reduces micro‑chipping and prolongs edge stability.

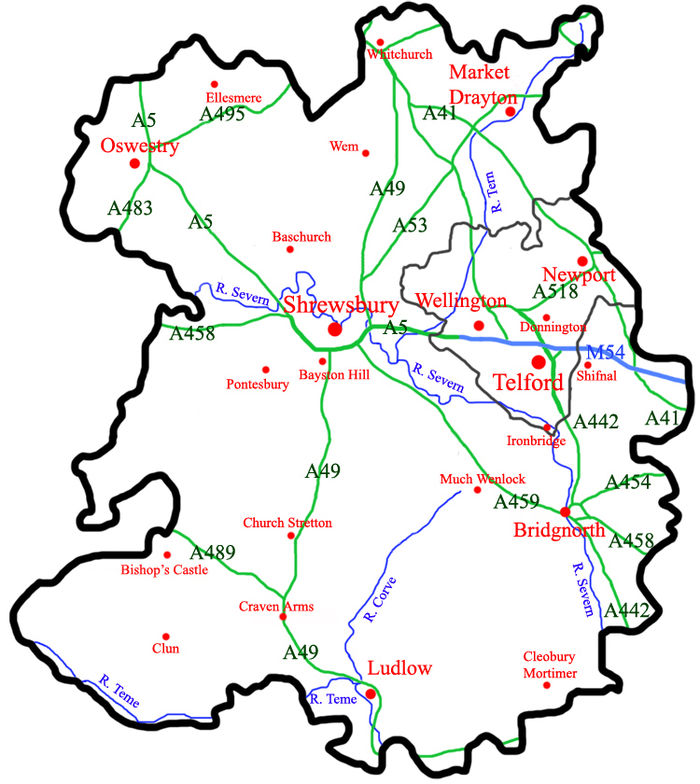

Riddles,

Back Lane

Bomere Heath

Shropshire

SY4 3PL

Our Location

Our Workshop