Take Note: all spam callers WILL receive short shrift

Our Sharpening Services

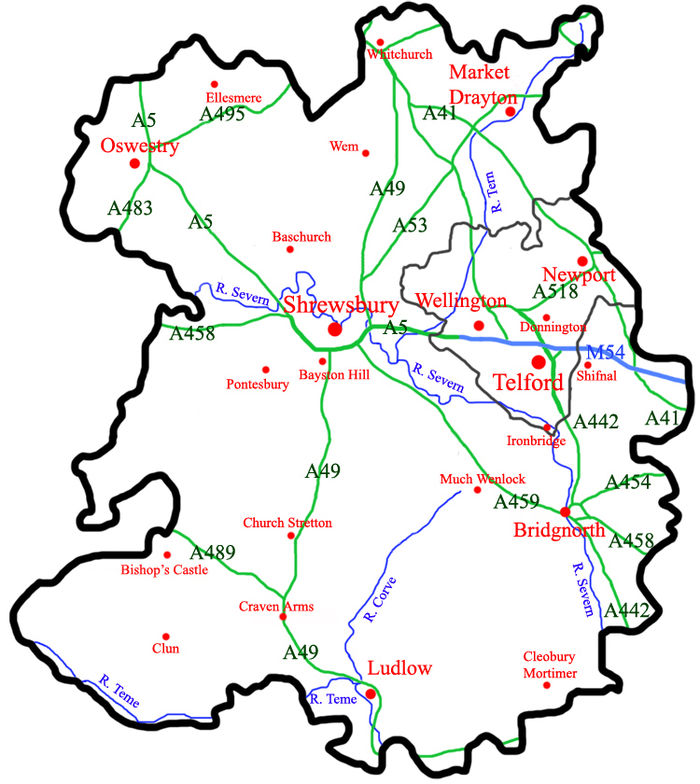

Local sharpening, National Sharpening, Mobile Sharpening

Professional Sharpening Services For You - Wherever You Are Located

We work locally and nationally — with Drop in, drop off, mobile, and postal options.

Whatever you need sharpened — from fine hairdressing scissors and chef’s knives to garden shears, clipper blades, or woodworking tools — our certified sharpening service is trusted by professionals and keen users alike. Whether you visit us in person, use our collection service, or post your tools in, we deliver top-quality sharpening with a fast turnaround and a personal touch

Please contact us to schedule a time to bring in your items. We often sharpen them the same day. For small items, such as a clipper blade or other tools like a mower blade, we would be happy to do it for you while you wait. However, we recommend calling ahead to confirm availability, as we may be out on a local job. If we are in the workshop, we will prioritise your work. Please see below for drop-off options if you arrive while we are away.

If we’re out when you arrive, no problem — you can leave your items in one of our secure drop-boxes just outside the workshop. We’ll let you know as soon as your sharpening is ready for collection. [See more details and photos of the drop-boxes here.]

f you’re within a few miles of Bomere Heath (SY4 3PL), we can collect and return your items for a modest fee. We also cover up to 15 miles from our base. If you have only a few items or are disabled, this may be free of charge. Call us to ask — we’re always happy to help where we can.

This is part of our B2B service. If you’re a busy chef, publican, or caterer with top-quality knives, we’ll come to your premises and sharpen them on-site. It’s quick, convenient, and ensures your tools stay in peak condition without downtime. [see more details here]

Not local? No problem. We offer a reliable nationwide postal sharpening service — so even if you’re in Cornwall or Caithness, we’re as close as your local Post Office counter. [Click here for full details on our mail order service.]

We Offer More Than Sharpening

While we sharpen and hone chef’s knives, professional’s scissors for hairdressers, dog groomers, seamstresses, industrial and other professionals’ items. We also attend to more seemingly mundane items and, if need be, we do not merely sharpen them; if required, we refurbish them or, out of necessity, repair them. Numerous items frequently require more than sharpening, such as wood chisels and secateurs; they need repair or servicing. Older items may require some attention, and many customers bring us items from the past that will respond to some care. Misuse is prevalent; wood chisels previously used to open paint cans are a common occurrence, almost as common as nail damage to the edge. Many hedge trimmers have inevitably cut hedging wire and need a new edge. Pinking shears that have lost their ability to “pink” after years of use are another frequent request from seamstresses.

We provide our services locally and via post and courier nationally. We possess equipment identical to the manufacturer’s production machinery. These machines are unique, so we have received specialised training on their use, hence being “Certified". This enables us to sharpen hairdressers’ scissors, preventing them from being sent to other countries such as Germany or Japan for rework.

Some Advice On Keeping Those Edges Sharp

Good Knives And Edge Tools Are Not inexpensive

Try Keep A Sharp Edge On Your Equipment

Proper Sharpening Is More Than Worth The Comparative Expense

Cut On The Right Medium

The surfaces that you choose to use for cutting directly affect the condition of your knives. You want to avoid hard or metal surfaces, such as stainless steel, granite, and aluminium. On the other hand, cutting on wood, plastic, or polyethylene is usually just fine. Your edges are likely to be safe as long as you are using a cutting board made out of the proper materials.

Wash Knives by Hand

Many folks toss their sharp knives in the dishwasher without a second thought. While it might seem like a quick way to get them clean, the intense heat, water, and detergent can quickly dull them. Instead, take the time to wash your knives by hand. Sure, it’s a good idea to sharpen them frequently, but handwashing will help them stay sharper for longer.

Store Your Knives Properly

In addition to putting knives in the dishwasher, some also put their good knives in with many other kitchen utensils in the “knife drawer.” But it’s best if your knives have a dedicated storage spot all to themselves. You can dedicate a whole drawer just to your knives but they still collide with other knives which inflicts damage. Wooden blocks or knife inserts for drawers are a good investment, being ideal for storage. Many private and commercial kitchens use a magnetic wall-mounted strip so that their knives are available for quick access with almost zero chance of edge damage. Such a magnetic system is not really ideal for homes with little children or pets.

Taking Care of Your Knives

When you take the time to take care of your knives, then you are less likely to run into problems, such as when ingredients tear when you are trying to slice them. Knives are a very important part of food preparation . Like any other tool that you use around your home, you need to make sure they are in good condition so as to produce the results you seek. Keep your knives sharp, store them properly and use them on the appropriate surfaces, they will serve you for much longer. It is good practice after we have sharpened your knife, rinse it with water (stay away from that edge - use a brush) and dry it with a soft towel, this to remove any excess metal shavings that we may have missed.

Enjoy the new sharpness of your blades and experience the results in easier preparation.

Scissors

The best way to help your scissors keep their edge is to clean them after use, never leave them wet..

Cutting aluminium foil will not sharpen them, adjusting the screw ever more tightly may well hasten their eventual demise.

Never sharpen them from the inner faces, that will turn them into so much scrap metal.

If your scissors are quality take them to a professional sharpener, if you are skilful with a abrasive stone you may get a slight improvement, but it has damage risks.

If you use scissors in your work it’s best to go to a pro to get them sharpened

Hedge Shears

Clean after use - each and every time, spray with GT85 / WD 40 or similar before storage, when the edge gone off take the machine to a pro sharpener such as ourselves, who for a few pounds you will give you a real ground edge at the right cutting angle. Always lubrcate your blades frequently when in use. The best lubrication for tha machine is chain oil as used in a chainsaw, this is very “sticky" so will not get fling off the blades and importantly it is bio degradable, much better than any other form of lubrication for these machines.

How to Damage A Knife In A Few Easy Strokes

The pull-through sharpener comes in many forms, and it does make a sharper edge than a completely blunt knife. But it’s not the best solution in the long run. The sharp edge is created by two crossed tungsten cutters that quickly wear away at the steel’s structure, often leaving a rough, serrated edge. This edge gets rougher and rougher with each use, and eventually, it breaks and shows signs of damage. It will cut, but it won’t last long before it needs to be sharpened again, and more damage is done.

When we’re asked to sharpen damaged knives, we do it in two stages. First, we remove all the metal to the depth of the deepest notch, which can take some time. Then, we shape the edge of 15 degrees on each side, for a total of 30 degrees. This is done using a special machine with an abrasive called CBN, which is a new material almost as hard as diamond but doesn’t put as much heat into the material, so it can be worked dry.

This new edge of 30 degrees is very sharp and durable, making it last a long time and cut well. Finally, we grind it under cold water on a stone to the correct angle and then hone it to make it smoother.

Here’s a before-and-after picture of the edge of an expensive set of Global knives that we recently sharpened in our workshop. The repairs and sharpening cost a fraction of the price of a small Global paring knife. These “knives for life” are now sharper than they were when they came out of the factory and will only need to be sharpened again if they’re damaged.

Close Up View - Not very Nice

Pull through sharpeners will destroy the edge of the knife, tearing at the steel it remove chunks large and small.. This is correctable by reforming the edge to the correct angles (usually 15° per side) and taking out the craggyness and any nicks that have been created. This picture is via our digital microscope of a client’s knife sharpened by this method

Close Up View - Very Nice

This is a ground and honed edge; typical of the ones we produce. If the knife is damaged as seen in the other photograph we have a dedicated machine to bring this back to a normal edge. When we have repaired the edge and taken the coarseness and nicks out of it we grind ir further to an accurate angle and hone it smooth on other machines

We Say Bin It

Hammer It Before It Hammers Your Knife

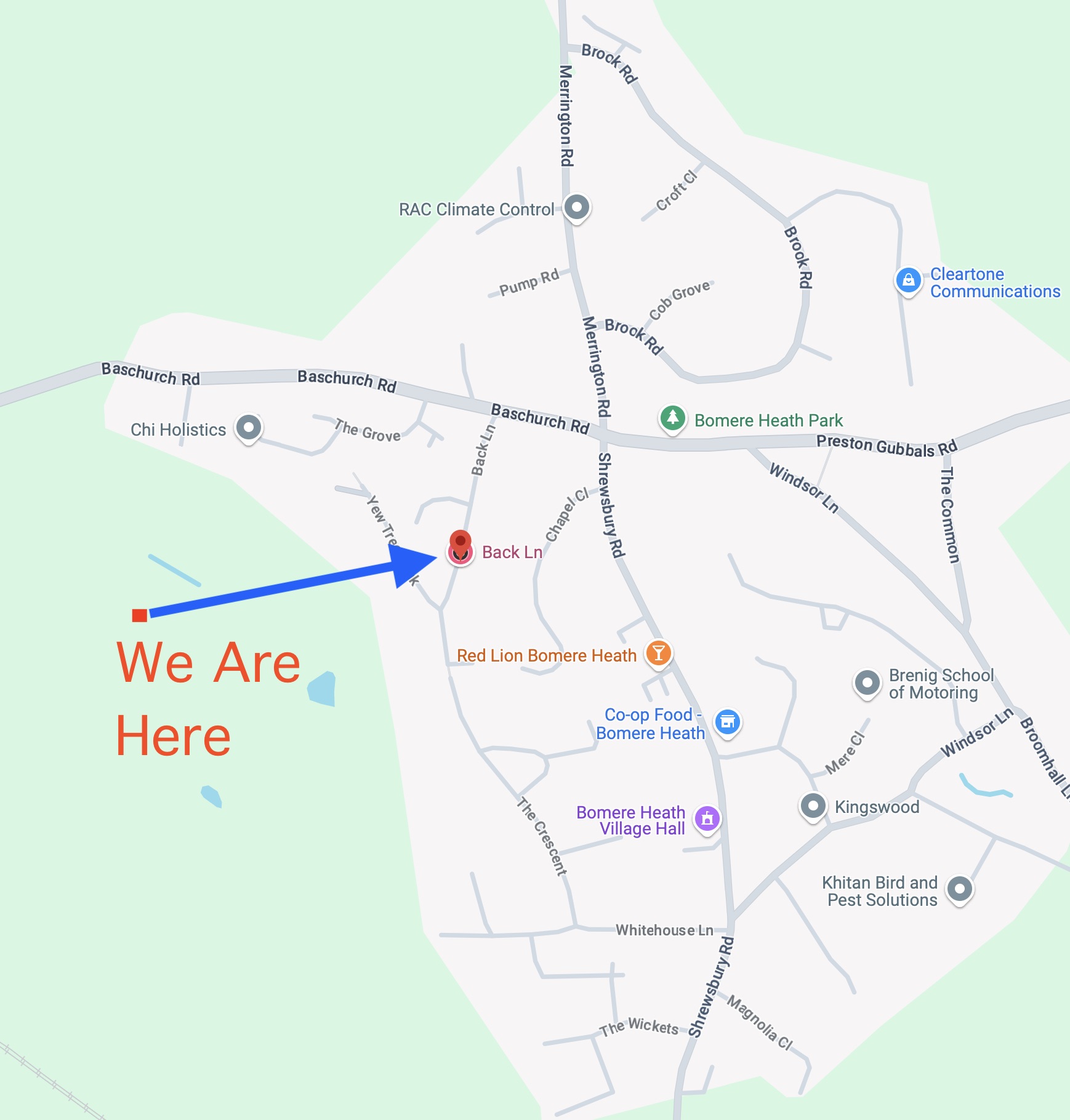

Address

Riddles,

Back Lane

Bomere Heath

Shropshire

SY4 3PL

WHAT 3 WORDS

(click on link for map)

seemingly.showed.launcher

Copyright © 2025

Built In House By Certified Sharpeners On A Mac Using Blocs