Take Note: all spam callers WILL receive short shrift

Clipper Blade Sharpening

Blade Sharpening

Will Reduce Your Effort

Sharpening Large Animal Clippers

Clipper Basics A2 A6 A7

Comparing A2, A6, and A7 Clipper Blades

A2 blades result in a shorter coat length compared to A6 blades. Consequently, A2 blades are classified as “medium” blades, while A6 blades are considered “more coarse.” A6 blades are typically used for extremely thick or matted hair on animals such as cattle, whereas A2 blades are suitable for most horse clipping scenarios.

Cutting Length: A2 blades leave a shorter coat length than A6 blades.

The primary distinction between A6 and A7 clipper blades lies in their suitability for challenging clipping conditions.

A6 Clipper Blades: These coarse blades are ideal for general clipping of cattle and horses, particularly on thicker coats. They leave approximately 3 mm of hair after clipping.

A7 Clipper Blades: These even more coarse blades are particularly suited for use on thick or somewhat dirty coats, commonly referred to as “Dirty Cattle blades.” They also leave approximately 3 mm of hair after clipping. Notably, A7 blades have fewer teeth on the comb compared to A6 blades, making them more effective in handling tough clipping conditions.

Clipper Blade Variations: Clipper blades are available in various lengths and tooth patterns to achieve distinct trim styles and coat lengths. Paradoxically, the higher the blade number, the shorter and finer the cut. For instance, a 50 blade is closer to the skin, while a 3 blade leaves the fur longer.

Sharpening with The Lightest Touch

Removing Minimal Metal

When we sharpen your A2 or A6 blades we remove the minimum material at every grind, giving you better blade life and less expense overall.

Sharpening Clipper Blades The Correct Way

We employ a Swiss-designed Heiniger machine manufactured by Linscop, a German company. This machine features a high-speed rotating, specially profiled micro-grooved aluminium disc (a conical profile) specifically designed for clipper blade sharpening. This disc is equipped with micro grooves machined into its face, similar to an old-style LP record. Prior to use, the disc is loaded with sacrificial oil as lubricant and abrasive powder, creating the grinding surface. We have two types of discs in our possession: A2, A6, and A7, which are specifically designed to accommodate large animal blades, such as horse and cattle clippers. Sheep clippers cannot be sharpened on the equipment we have.

Certified Sharpeners think this is a better approach than other machines that have one design suiting all blades but not maximising and the geometry and optimising performance.

Clipper Tension & Lubrication

Clipper blades require precise tension adjustment, which determines the force exerted between the comb and the cutters.

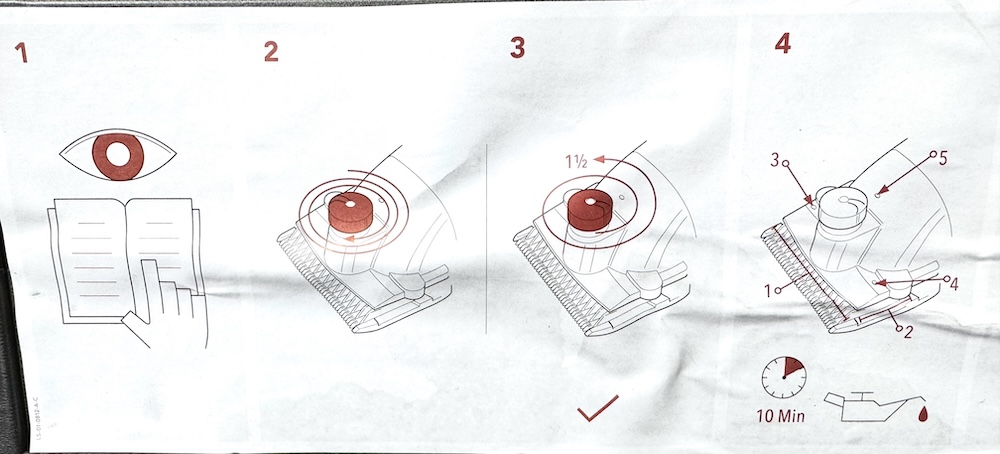

A straightforward procedure involves fully tightening the blades and then gradually reducing the tension by one and a half turns, as indicated in the standard operating instructions. Additionally, it is advisable to lubricate the blades every ten minutes of use with clipper oil (preferably high-quality Pure Mineral Oil - pharmaceutical grade), as illustrated in the accompanying image.

We don’t do powered sheep shears

but we do Sharpen Dagging Shears

Click For Dagging shears

The Specialist Grinder

Looks simple but in fact it’s not. The working surface has a conical profile and machined into a grooved aluminium disc. Oil and grit is pushed into the micro grooves making it a grinding wheel that can be refreshed. The high speed rotating disk hollow grinds clipper combs and cutters with great precision - the blades are not ground flat unless they are off an adjustable clipper. Don’t ruin yours on a diamond hone.

Enough and Not Too Much

The Ideal grind is to remove no more than 0.002” nor too little, not to get the work hot either. So we use a precision measuring device to give us the accuracy we need as to the amount removed. We measure before during and after the grind checking on completion for the value we seek. This will indicte to us the number of grinds left on the blades.

The Hollow Grind

We grind in such a way that results in a specific style of hollow grind. This to maximise the cutter life, minimise heat, chatter and efficacy of the cut from your clippers. Post gind the blades are washed in a degreaser and finally given a long spell in an ultrasonic cleaner using bactericide mixture so they’re clinically clean.

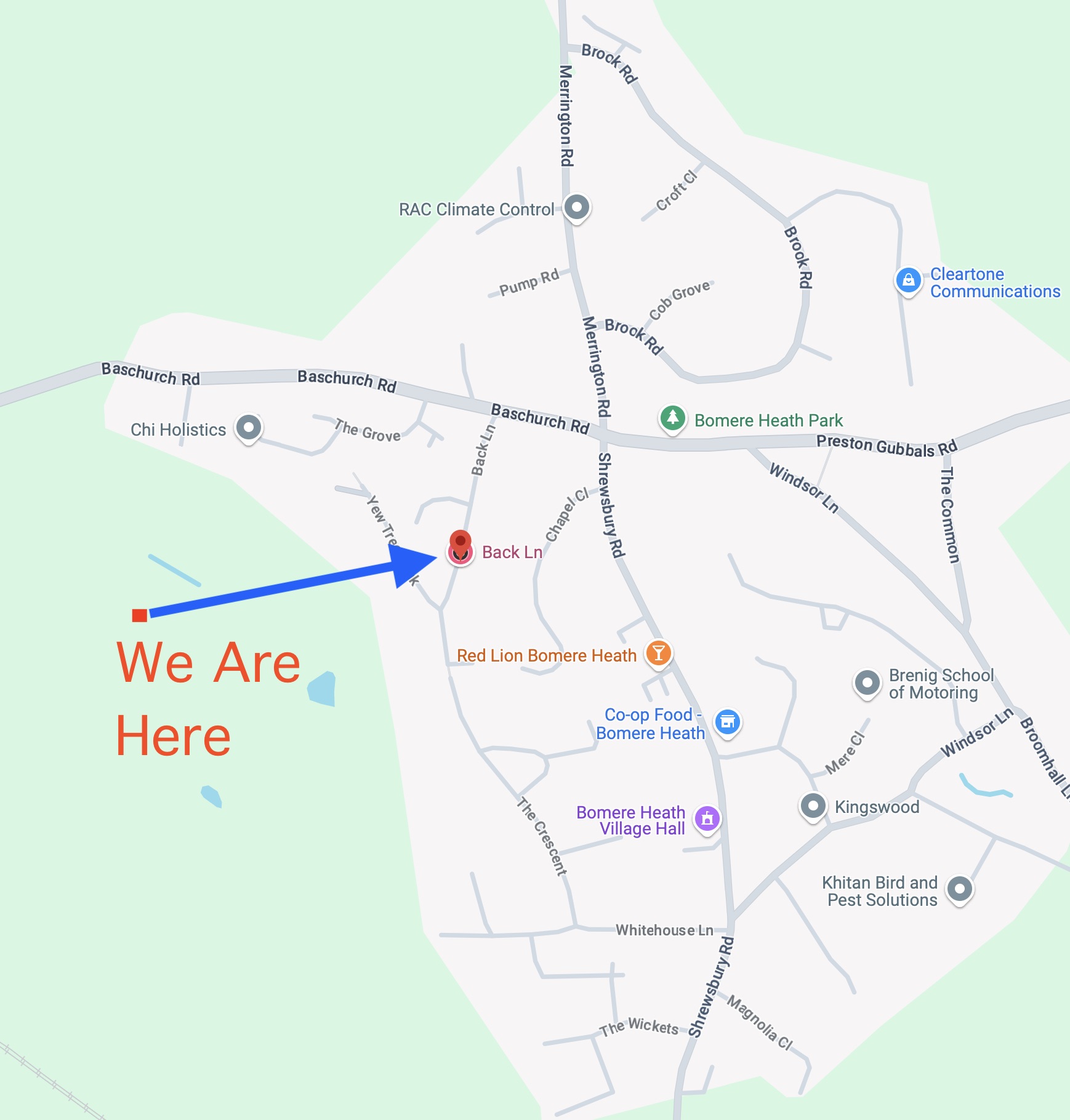

Address

Riddles,

Back Lane

Bomere Heath

Shropshire

SY4 3PL

WHAT 3 WORDS

(click on link for map)

seemingly.showed.launcher

Copyright © 2025

Built In House By Certified Sharpeners On A Mac Using Blocs