Take Note: all spam callers WILL receive short shrift

Sharpening Knives

Sharpened Speedily

In Search of the Ultimate Edge

A Knife Has To Be Sharp

There’s no point having a blunt knife; sharpness is the reason for the blade’s very being. Certified Sharpeners have the know-how to produce that ultra edge and replicate it with extreme accuracy on almost any blade, producing a product that usually outperforms the ex-factory product.

A good knife is a good tool; a good knife that’s sharp is an excellent tool, producing paramount results with minimal effort.

Sharpening Chef’s Knives

King of the professional chef’s tools is the knife. Costing considerable amounts of money and very much cared for by their owners, they need to be sharpened by equally dedicated and qualified professional sharpeners.

We are often asked which knives we recommend, and it’s products not from overseas as you might have assumed but from a very long-established British maker from Sheffield, the place stainless steel was invented, and they’re called Samuel Staniforth. They’ve been in business for 160 years, so we can be sure they really know what they’re doing with knives and steel.

Single Sided Craft Japanese Santoku Knives

Sharpening Kitchen Knives

Domestic users may not have the quality of knives the Chef uses but many keen cooks do. However that does not mean they have to accept second best the mundane kife of no repute deserves. to be good and sharp. We use exactly the same processes to get the keenest practical edge.

Sharpening Other Knives

Knives of course come in many shapes, sizes and variety of duties. That doesn’t really matter too much as most follow the came principle. Some are flexible, some stout, some pointy, some straight. It matters not the same priciples apply and the outcome is a sharpened blade and we can sharpen those herb knives (Mezzaluna) that need a keen esge to be effective

Our Sharpening Process

Repairs and Preparation

The first thing we so is inspect the blade, it’s rare for them to be perfect. All we see are of course blunt but they may be nicked, torn or be damaged in some other way, a broken tip or bellied blade. We pre grind almost every knife in a machine that gets the blade smooth, with no nicks and is equally bevelled to an angle of around 15°. This is done dry but using a special abrasive CBN or Cubic Boron Nitride, this has the unusual charicteristic of producing very little heat in the process of material removal so the hardening of the knife is undamaged

The Wet Grind

We use a dedicated machine from Sweden called the Tormek T8 to finish grind knives. This has a water immersed grinding wheel with various grade grits. When we grind on this the waste metal is washed away with the water and collected by magnets and the blade is kept litrally stone cold by the water.

The Set Up

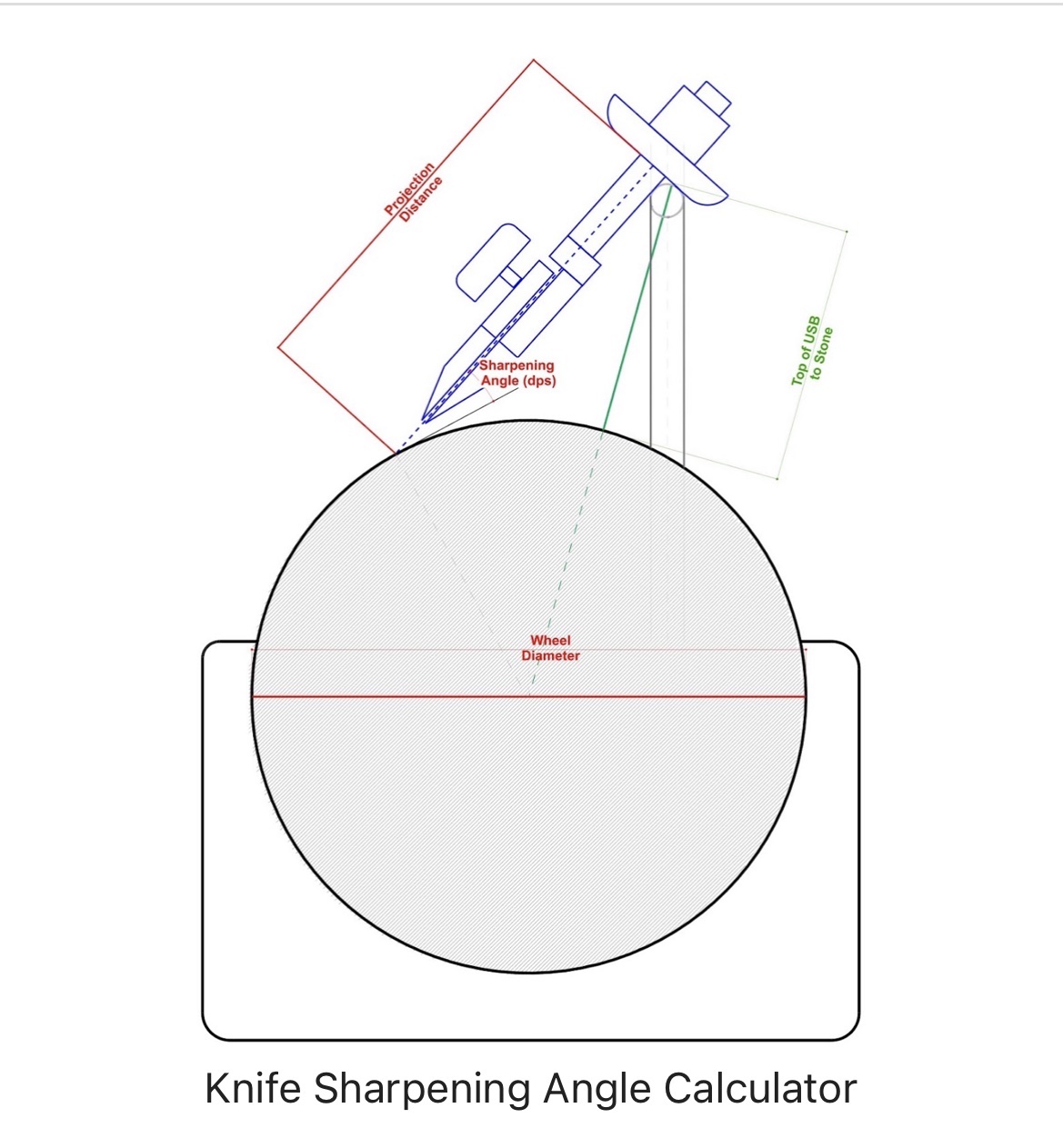

Implementing some trigonometry is key: known is the grinding wheel diameter which we are about to use (250mm is the norm.)

In the dedicated jig we set the distance to the blade edge to a known amount (say 140mm) if the edge angle we need is say 15° then it’s possible to calculate the distance from the wheel to the jig rest setting the height of the jig rest. This way, we arrive at the grind angle spot on each and every time, irrespective of the variable blade widths we are grinding

Sharpening Under Water

Our Tormek T8 ginds a new edge while underwater, zero heat is generated and passed to the blade, no loss of temper so no damage and minimal material removed with all the cut metal is flushed away and captured by magnets.

The Hone

We use several honing techniques, the methods and materials used are dependent on what products we are working on, here is a polishing mop with white grade polishing media designed for stainless steel

The Polish

One final polish on the mop with nothing added to make for a good finish.

The Final Cut

Will the new sharpened edge perform? This one certainly does - all are tested like this

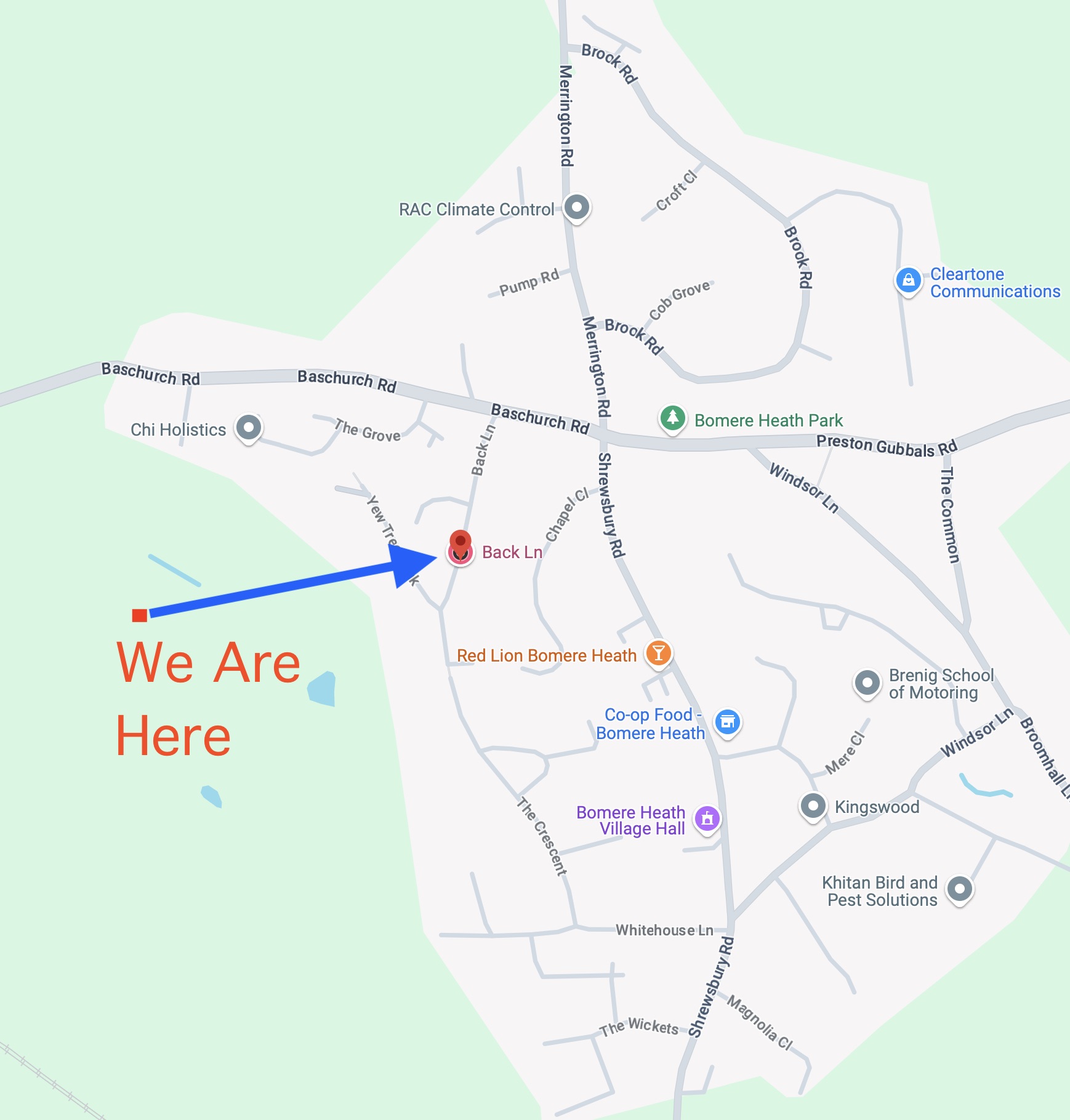

Address

Riddles,

Back Lane

Bomere Heath

Shropshire

SY4 3PL

WHAT 3 WORDS

(click on link for map)

seemingly.showed.launcher

Copyright © 2025

Built In House By Certified Sharpeners On A Mac Using Blocs