07517 434947

Certified Sharpen’s Latest News

Follow our updates here.

Training

June 2021

During a multi-week back-to-school experience, we engaged in one-on-one training with experienced long-term sharpeners.

Initially, we assessed our skills and experience levels and developed a comprehensive training programme that incorporated both practical and theoretical instruction. Although we had some prior knowledge of machinery, we were exposed to various devices from different manufacturers. This resulted in hands-on training and examinations.

Armed with the knowledge of the most suitable machines for different applications, we commenced our purchasing programme for new dedicated machinery that we were previously unaware existed.

Upon successful management and examination of outcomes, we received certifications for several machines. Subsequently, we acquired additional machine certifications from other reputable sources.

The training involved a significant amount of theoretical content, accompanied by extensive note-taking for long-term review and recall. While it was a challenging experience, it was ultimately worthwhile.

Back To The Grind

July 2021

Intensive training over we now make an effort on other aspects of the business. Summer is in full swing and there’s the everyday demand for garden equipment. Polishing and sharpening the humble spade pays dividents effort wise as does touching up the half moon lawn edger. `In a few months time we wil see a different crop of gardening tools arrive in the workshop as summer drifts into Autumn and the days shorten once more

New Machinery Arrives

August 2021

We have had several pieces of new machinery delivered but what you see here is our bread and butter scissor machine set up for domestic and general purpose scissors. It can be changed around to suit Left Hand Scissors. It’s called the “Twice As Sharp” as it does produce an edge thats twice as sharp as many seen ex factory. We can change the usual grit grinding wheel for a diamond unit - it then becomes the “Okami Gold” so called as the diamond wheel is gold in colour. We use that set up for high end hairdressing and grooming scissors. Those have highly polished cutting edges, however, on domestic and general purpose scissors this polished edge would cause the item being cut to push along the blade. Leaving the edge a little more rough allows the scissor to grip it as it cuts it.

Getting the Best Out Of it

Late 2021

Covid is still persisting so many eating houses are closed because of restrictions. Few chef’s knives are being worked on but the domestic market is as good as ever. Chef’s knives need the smallest level of attention as they never drive them into total bluntness and have them touched p frequently. We grind knives to very precise angles, and have to guarantee repeatability. We use a special jig on a dedicated machine the Tormek T8 and a little bit of complex trigonometry to set it up. This method uses 3 vitals the diameter of the grinding wheel, the distance from the stone to the rest for the knife holder - seen here using a Vernier gauge. and the distance to the edge from the same bar (via a blade holder) we can calculate with high precision the grind angle we achieve. Domestic knives are set up to have an edge angle in total of 30° or 15° per side if not single sided, chef’s and high calibre knives with very hard steels can go down to 20° or 10° per side. Even we call that scary sharp. It does have drawbacks though as the edge is more fragile and has a limited life as damage can occu

Sophisitcated Machinery For Convex Scissors

December 21

Here you can see our Hira-To, thiis is a highly specialised machine designed to achieve the optimal edge on Convex Scissors. Convex scissors are exclusively utilised by professional hairdressers and dog groomers, renowned for their exceptional sharpness and cost. Consequently, they require meticulous attention and care.

The process of sharpening a Convex Scissors involves employing a series of fine abrasives. Initially, the edge is typically prepared to approximately 40 degrees, and subsequently, it is gradually polished until it aligns seamlessly with the convex shape of the blade’s top. This final polishing step is achieved using diamond honing paste on a felt pad.

Mastering the technique of achieving this professional edge and finish requires both practice and time. During the COVID-19 lockdown, we dedicated some time to refurbishing old practice scissors to maintain our muscle memory and proficiency.

Getting Some Balance

March 2022

Spring is knoocking on our door it’s theetime of year when many individuals who plan ahead, particularly gardeners, preparing their mowers, becomes particularly pertinent. A sharp blade efficiently cuts the grass rather than tearing it, resulting in a noticeable difference in the outcome. Most blades can be sharpened multiple times, depending on the extent of wear and tear they have sustained during use.

As a final step, we balance the blade to ensure optimal smoothness during mowing.

Groovy Man Micro Grooves in Scissors

Summer 2022

We have acquired a very specialist high-end Corru-Gator machine equipped with a unique slow-speed diamond wheel. This wheel cuts microscopic grooves into the edge of a scissor blade, preventing the material from being pushed along the blade. Professional pet groomers prefer this modification to standard scissors because animal hair is tougher than human hair and tends to slide.

There are also industrial applications for specialised materials such as aramid and carbon fibres, which are difficult to cut. These materials require specialised dedicated shears that require a precise finishing touch.

The finishing Touch

Nov 2022

Sharp edges necessitate protective measures, and users require similar protection from these edges. Given the diverse range of items requiring sharp edges, their shapes and sizes must be accommodated.

After thorough research, an effective solution for finishing scissors, clipper blades, chisels, and other pointed tools was identified. This solution employs a hot dip coating of strippable wax. Removable and partially reusable, this method offers exceptional protection against transit damage and potential cuts.

Mail Order Sharpening

January 2023

We have been asked many times if we do mail order sharpening across the UK. Some customers pressed us sufficiently for us to run a pilot scheme and it works well so we’re rolling it out now. We have a dedicated page at this link.

House Call Sharpening

June 2023

The majority of our equipment is workshop-based, large, heavy, and wet. However, after consulting with the Cutler’s Association in Sheffield, we have discovered a machine that produces knives with an optimal edge through a cold, dry grind. The CATRA sharp is lightweight, portable, and employs CBN abrasive. Cubic boron nitride (CBN) is an exceptional abrasive material specifically engineered for advanced wear-resistant properties. This relatively recent technological innovation has been recognised as one of the greatest recent advancements in abrasive materials.

Approximately as hard as diamond, CBN can be utilised in appropriately designed machines to grind without significant heating of the edge resulting from material removal. Our CATRAsharp can be dispatched to your premises to perform knife sharpening services.

New Surface Grinder Arrives

November 2023

We have acquired an specialiity surface grinder to make more accurate finishes possible on Planer blades.

We spoke too soon and decided the demand was so low to withdraw this service from our offerings. Most planers in the market we serve use throway blades that cannt be properly re edged.

We would adise for larger itsm then Fernite in Craven Arms will help.

Better than before

May 2025

From the outset, we have been sharpening saw chain. If you have ever sharpened a chain using a file, you will understand the tedious nature of the task. When we opened, we utilised my personal grinder, which had been in use for many years. Unfortunately, it eventually began to deteriorate, necessitating the purchase of a new machine.

We opted for the top-of-the-line product from the renowned chain and bar manufacturing company, Oregon. This precision engineering marvel is constructed entirely of metal and features sturdy die castings. These components ensure that the precise angles for the chain grind are maintained and replicated consistently. Consequently, every known chain from major manufacturers can be restored to factory specifications. Additionally, the depth gauge can be reset, thereby optimising the cutting performance of your chainsaw and saving fuel, effort, and time.

Close to Diamond

December 2025

Powder knives are becoming more mainstream. Unfortunatley, and many new users do not realise, normal abrasives will not work on these steels. Specialist materials are needed, diamond will work but is chemically challenged by the iron molecules in the steel. A synthetic material abrasive CBN (Cubic Bornon Nitride) is very nearly as hard as diamond and is not subjected to chemical attack.

We have responded to the growth in powder knives and while the CatraSharp is CBN equipped it can only produce a 30° (15° x 15°) edge.

We have aquired a CBN wheel for the Tormek T8 and we can replIcate the 11° 12° 13° & 14° grinds used on the ultra hard steels

Heading content

December 2025

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim.

Riddles,

Back Lane

Bomere Heath

Shropshire

SY4 3PL

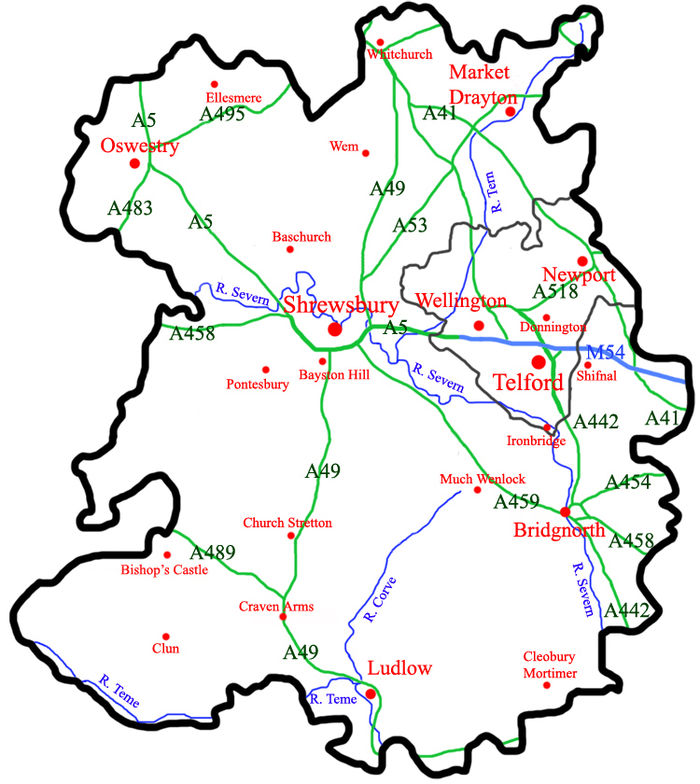

Our Location

Our Workshop