Take Note: all spam callers WILL receive short shrift

Scissor Sharpeners

A Sharper edge makes the physical work easier on you

Expert Scissor Sharpening Services

Scissor Sharpening Service – Hairdressing, Grooming & Tailoring Serving al the UK from our base in Shrewsbury

👉 “Drop your scissors in to us in Shrewsbury today — we’ll return them sharp and silky smooth within 24 hours.”

Types of Scissors We Sharpen

We sharpen all kinds of scissors to the highest standard, restoring factory-quality performance. Whether you use them at home, in the salon, or professionally, sharp scissors make every cut effortless.

Types we work on include:

• Hairdressing and barber scissors

• Pet grooming scissors

• Dressmaking and tailoring shears

• Pinking shears

• Embroidery and craft scissors

• Kitchen and general-purpose scissors

Hairdressing And Barber Scissor Sharpening

Hairdressing scissors demand precision. Our sharpening process restores the exact edge and angle your scissors were designed for, ensuring clean, smooth cuts that protect hair health and reduce your strain

•Convex and bevel edges

•Japanese and European styles

•Includes tension and balance checks

Ideal for: salons, mobile stylists, barbers.

•Factory angles maintained → that means your shears feel “new” again and cut dry or wet hair cleanly.

•Set and ride line checked → that means smooth, even closing with no grab or crunch.

•Honing to 50–55° where appropriate → that means longer-lasting sharpness between services.

Sharp grooming scissors mean safer, faster, and more comfortable cuts for pets. We sharpen straight, curved, and thinning scissors used by professional groomers and pet owners.

Why it matters:

•Prevents hair-pulling and discomfort

•Maintains clean, precise lines

•Extends the life of your tools

• Reduces your fatigue

•Micro-serration available → that means better control on dense or curly coats.

•Tip alignment and tension set → that means safer trimming with fewer snags.

•Corrosion-safe finish → that means easier cleaning and longer tool life.

Tailoring And Seamstress Scissor Sharpening

From budget household scissors to premium brands like Zwilling or Whiteley, we handle them all. These high-quality scissors often become family heirlooms—some arrive at our door after decades of use, ready for renewal.

•True to maker’s profile → that means consistent cuts from tip to heel on fine or heavy cloth.

•Pivot and set adjusted → that means less hand fatigue on long cutting sessions.

•Optional light micro-tooth → that means improved grip on slippery fabrics.

Pinking Shear Sharpening

Pinking shears are unlike any other scissors. Instead of being ground at a positive cutting angle, they require a negative angle (from 0° to –5°) to restore their cutting edge. This demands specialist equipment such as the Twice As Sharp system from Wolff Industries. With the right set-up we can bring blunt or snagging pinking shears back to life, so they cut cleanly through fabric once more.

•Heavy-duty edge geometry → that means reliable cutting on composites, webbing and tough materials.

•Heat-resistant finish options → that means durability in production environments.

•Consistency across pairs → that means predictable results on the production line.

Domestic Scissor Sharpening

These could vary from the almost a really inexpensive product, typified by flimsy flat blades with plastic hand pieces to the lifelong products from quality makers like Zwilling or Whitely at £50 or more; these top end products tend to be passed to following generations some of who turn up at our door wanting a sharp edge put back - we can of course do that and also the pair from IKEA.

Industrial Scissor Sharpening

Industrial scissors are built for heavy-duty use in manufacturing, textiles, upholstery, and other demanding applications. We restore their cutting performance to like-new, reducing operator fatigue and ensuring precision on tough materials.

👉 “Drop your scissors in to us in Shrewsbury today — we’ll return them sharp and ready within 24 hours.”

👉 “Send us your scissors by post — click here for packing and posting instructions.”

Sharpening Scissors On The Best Equipment

There are three major kinds of scissor edges are found in the mainstream. Here’s the equipment we use that sharpens them to factory specification or better

Twice As sharp

The industry standard scissor sharpener is the "Twice As Sharp” This is made by renowned USA shear manufacturer Wolffe industries, who uses these machines in daily production of their top end products

Hira-To

This is the professional sharpenre's preferred flat hone machine usedfor the sharpening of and re profiling fully convex scissors. It can also be used to re edge thinning scissors.

Okami Gold

We use a dedicated diamond wheel on the Twice as Sharp, then a unique hone specifically for hairdressing and animal grooming scissors.

Corru-Gator

This is the professional sharpener's most effective way of adding grooves (72 or 48 per inch) to groomer’s and industrial scissors. Producing better results than the traditionall specialist grooving file.

For some users there is a more coarse cut 48 groves per inch for special duty scissors for poultry, kevlar, carbon fibre and other tough to cut products

Whetstones

Water and some frim but gentle strokes on the ultra fine whetstones we use make the rideline, the part where the cutting edges meet, perfectly flat and mirror like. The scissors the glide shut cutting with little noise after this treatment. We flatten the stones frequently to ensure precision.

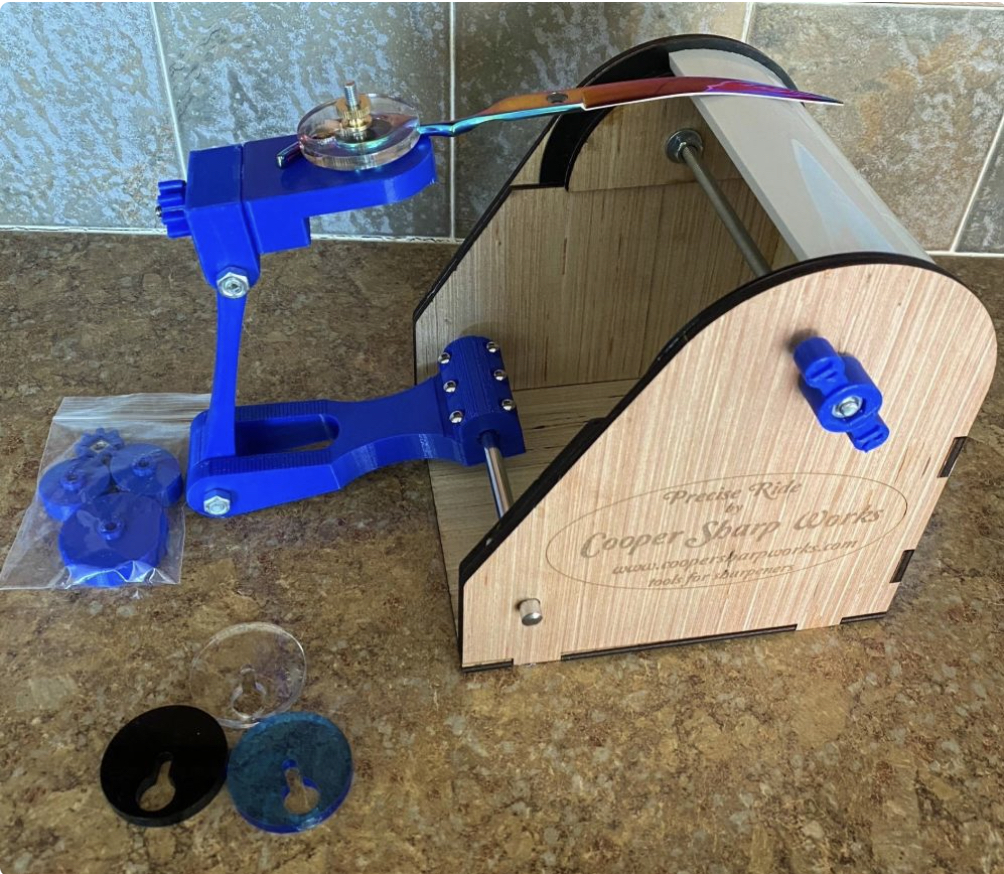

Pricise Ride

Can’t make a rounded rideline on the ever more popular curved grooming scissors on the tradditional whetstone so we have invested in the "Precise Ride" to reproduce that factory edge with precision and ease, offering better cutting power all round the curve.

✔ Drop your scissors at our Shropshire workshop or request our UK-wide mail-in service for fast, professional sharpening.

✔ Contact us to ask about bulk or trade sharpening for salons, tailoring shops, or factories.

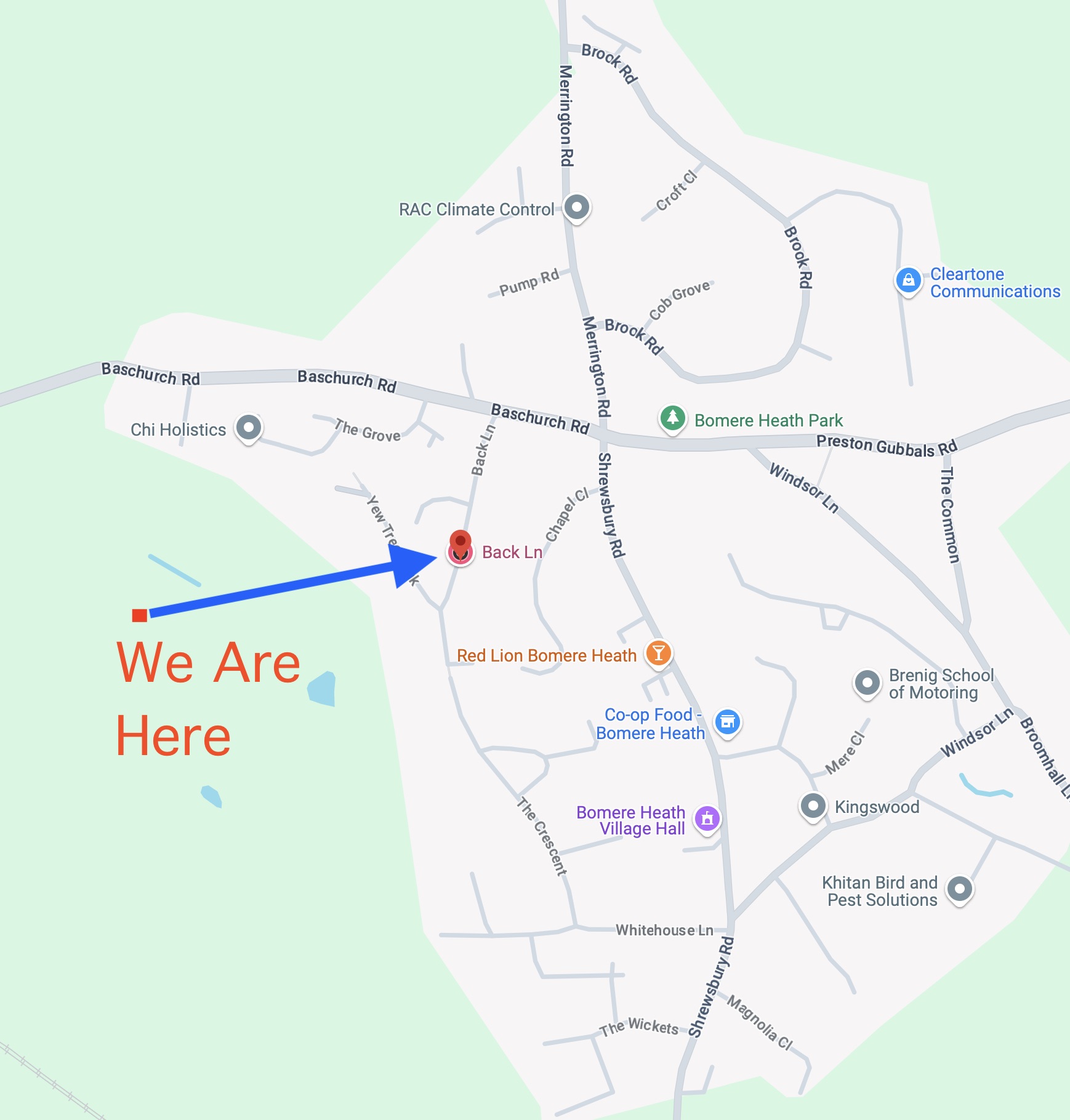

Address

Riddles,

Back Lane

Bomere Heath

Shropshire

SY4 3PL

WHAT 3 WORDS

(click on link for map)

seemingly.showed.launcher

Copyright © 2025

Built In House By Certified Sharpeners On A Mac Using Blocs