07517 434947

The Sharpening Capabilities of Certified Sharpeners

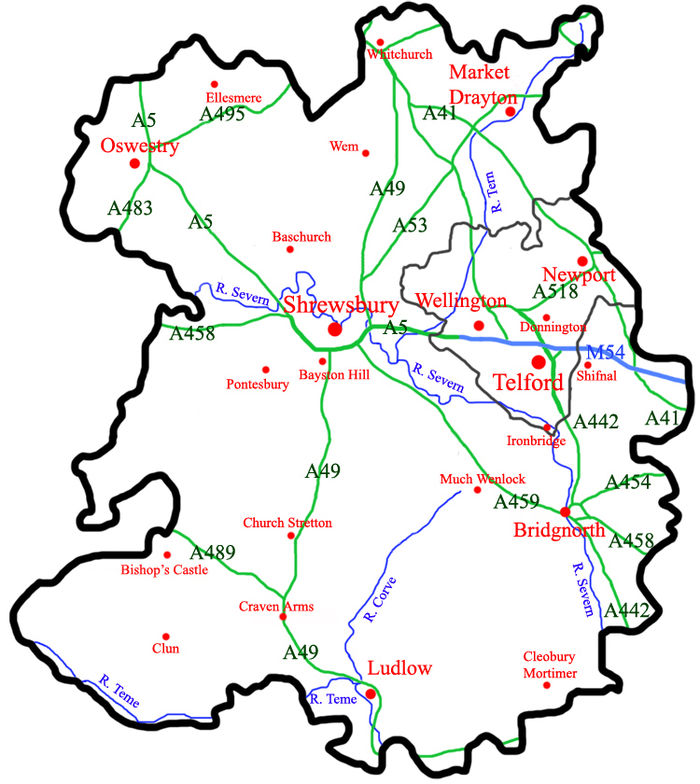

Certified Sharpeners are based in Shropshire, serving customers locally and across the UK via secure mail and courier service. weOur business is to restore the cutting performance of a wide range of tools — from everyday kitchen knives to specialist woodworking, grooming, gardening, and agricultural equipment. Whether it’s for home, trade, or industry, we sharpen it precisely, cleanly, and safely.

We use dedicated machinery to produce accurate and repeatable results. Operatives are trained and examined by the machinery manufacturers or their agents of the machines seen below assure you that only those with appropriate skill and knowledge work on your items. These unique machines, designed to produce the ultimate edge of particular items from scissors to chainsaws. Our investment in this dedicated machinery and training their use is the route to the best performance and repeatability we offer.

Or Click On The Pictures or Links Below To Go To The Dedicated Page.

Pet, Equestrian And Cattle clipper blades – cleaned, honed, and reset

Arborist equipment – saw chains and Hedge cutters professionally sharpened

Garden tools – secateurs, loppers, hedge Shears, Spades Hoes

PM Powder Knives, Hi Tec Steel Blades That Are Impossible To Sharpen With Conventional Abrasives

Whether you’re a professional or a perfectionist, sharp tools mean less effort, cleaner results, and faster work.

All sharpening is carried out in our dedicated workshop using specialist machinery sourced from leading manufacturers in the USA, UK, and Switzerland.

Industry Trained and Certified On These Machines

We are formally trained and certified in the correct use and maintenance of specialist sharpening machinery manufactured in the USA, UK and Switzerland, ensuring consistent geometry, edge retention and tool longevity.

The Twice As Sharp

A scissor sharpener from a scissor manufacturer in the USA using grit or diamond abrasives with blade angles form -5° to +40

The Hira-To

Specifically for the sharpening of semi and fully convexed scissors as used by hair stylists and dog groomers.

The Corru-gator

Some scissors have the blade (usually one) finished with micro grooves, hair and pet groomers use 72 teeth per inch, industrial users cutting kevlar® use 48 TPI. This machine with a special diamond wheel finishes to these standards

The Tormek

The classic Tormek T8 with dozeens of specialised Jigs can ssharpen almost any item from twist drills to penknives, plane irons and wood chisels using water to cool the work

The CatraSharp

From the Sheffield consultants Cutlers and Allied Trades Association comes the small but effective knife sharpener. Equipped with CBN cold grind wheels this will put a 15° x 15° edge on even tha hardest steels.

The Buffer

Sharpening usually produces a burr, in most instances its best removed we do this on a two stage buffing system using aluminium oxide impregnated wax applied to a cotton high speed buffing wheel then a final polish on a plain cotton wheel

The ProEdge

This machine come from possibly the best chisel maker in the UK - Robert Sorby of Sheffield, we utilise this to sharpen wood chisels to precise angles and using dedicated jigs to finish complex curves found on woodturning tools.

The Heiniger

A conically profiled disc running at high speed with abrasive compound on the surface gives the clipper blades the right slightly hollow ground finish, this is used for A2 and A5 blades with slightly different wheels and abrasive grit sizes

Oregon Grinder

It is easy to sharpen a chainsaw chain with a file, its less easy to keep the angles correct, it’s also time consuming if the chain is damaged or well worn. Arborists and many wood burner owners use our regrind service to get the angles right and get rid of the damage and of course they use them hard so they would rather not spend time on this tedious work. We use a machine from Oregon the saw chain makers for these tasks

The Knife Maker

This open loop large belt grinder is used for many functions from garden machinery re edging to knife repairs. The machine’s strength is its versatility and great variations in the belt type extends the working possibilities.

Whetstones

While we do not use whetstones to sharpen knives we do use them to rework scissors edges, Expensive shears have a “ride line” which, after sharpening the semi or fully convex scissor, needs re-establishing perfectly flat. Our stones are flattened frequently, seen here is a 6000 grit stone for polishing the ride.

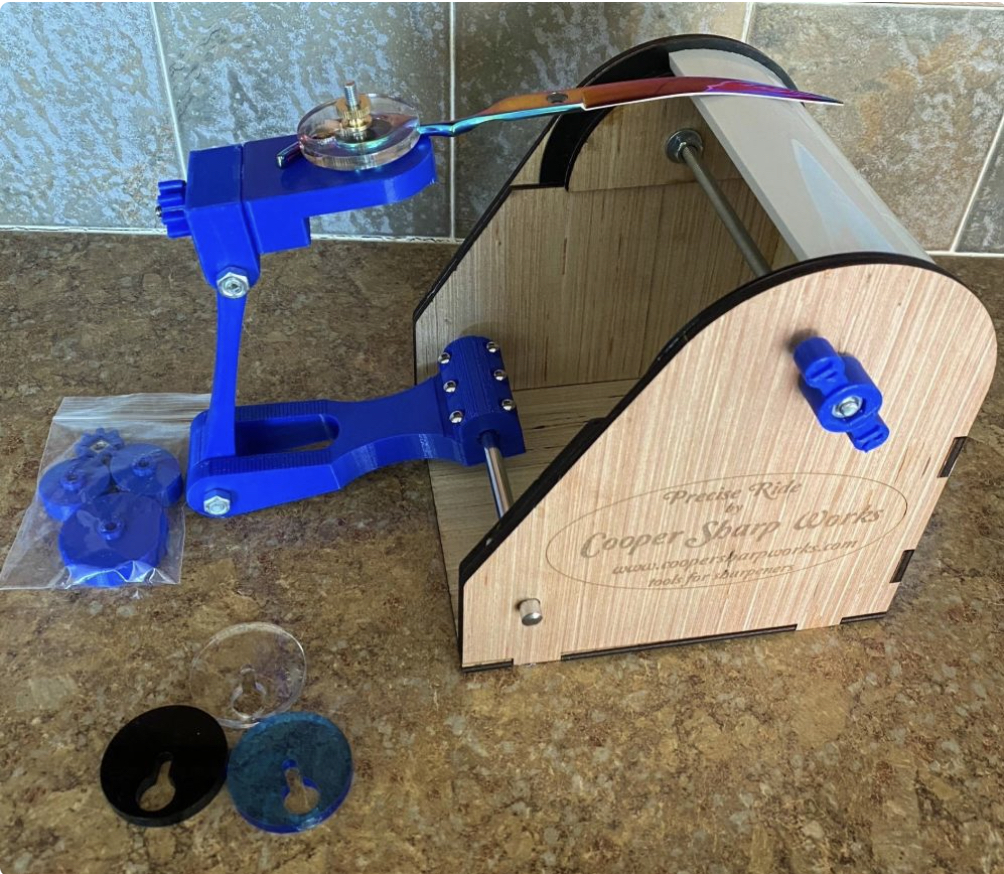

Precise Ride

Curved scissors demand very different treatment to the average pair of shears. This device puts the perfect “ride line” on curved scissors. The inward curved blade cannot be serviced unless using a curved bed of abrasive with a large base diameter such as seen here.

Riddles,

Back Lane

Bomere Heath

Shropshire

SY4 3PL

Our Location

Our Workshop